SyncWorks Key Features

"SyncWorks" offers a comprehensive set of modules and functions covering all aspects

of manufacturing operations. Each module serves a specific purpose, and together

they create synergy to build an optimized production environment.

Our Feature

Production Planning & Scheduling

Uses demand forecasting to create optimal plans, automate work orders, and improve delivery performance.

Schedule

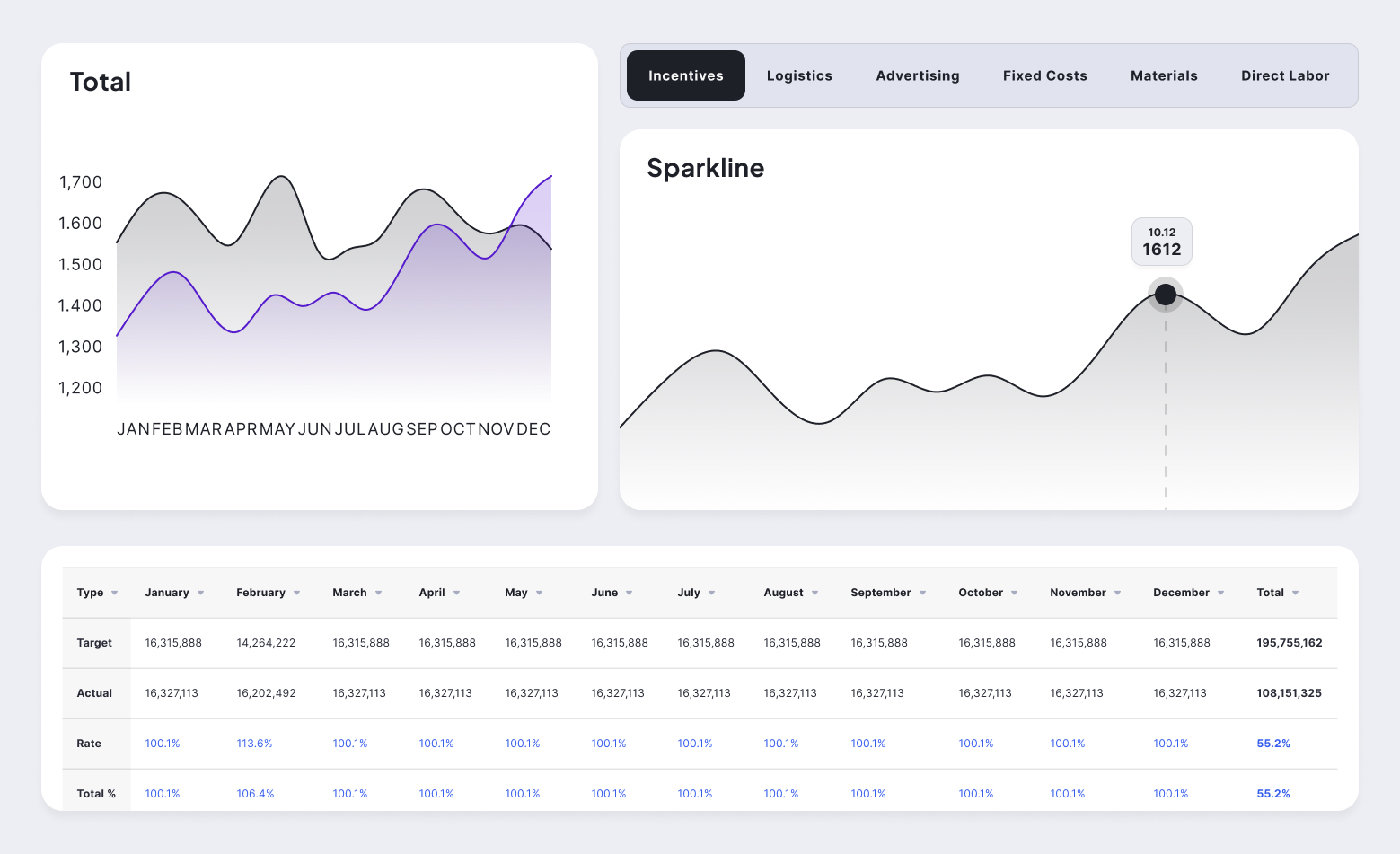

Production Monitoring

Provides real-time dashboards for output, utilization, and defect rates, with anomaly alerts and remote monitoring.

Monitoring

Quality Management

Controls inspection standards, identifies defect causes, and auto-generates quality reports.

QC(Quality Control)

Equipment Management

Supports preventive maintenance, predicts failures, and analyzes OEE (Overall Equipment Effectiveness).

Equipment Management

Material Management

Monitors inventory in real time, manages material flows, and enables LOT traceability.

Materials Control

Production Traceability

Keeps detailed product histories, tracks processes from raw materials to finished goods, and enables fast recall response.

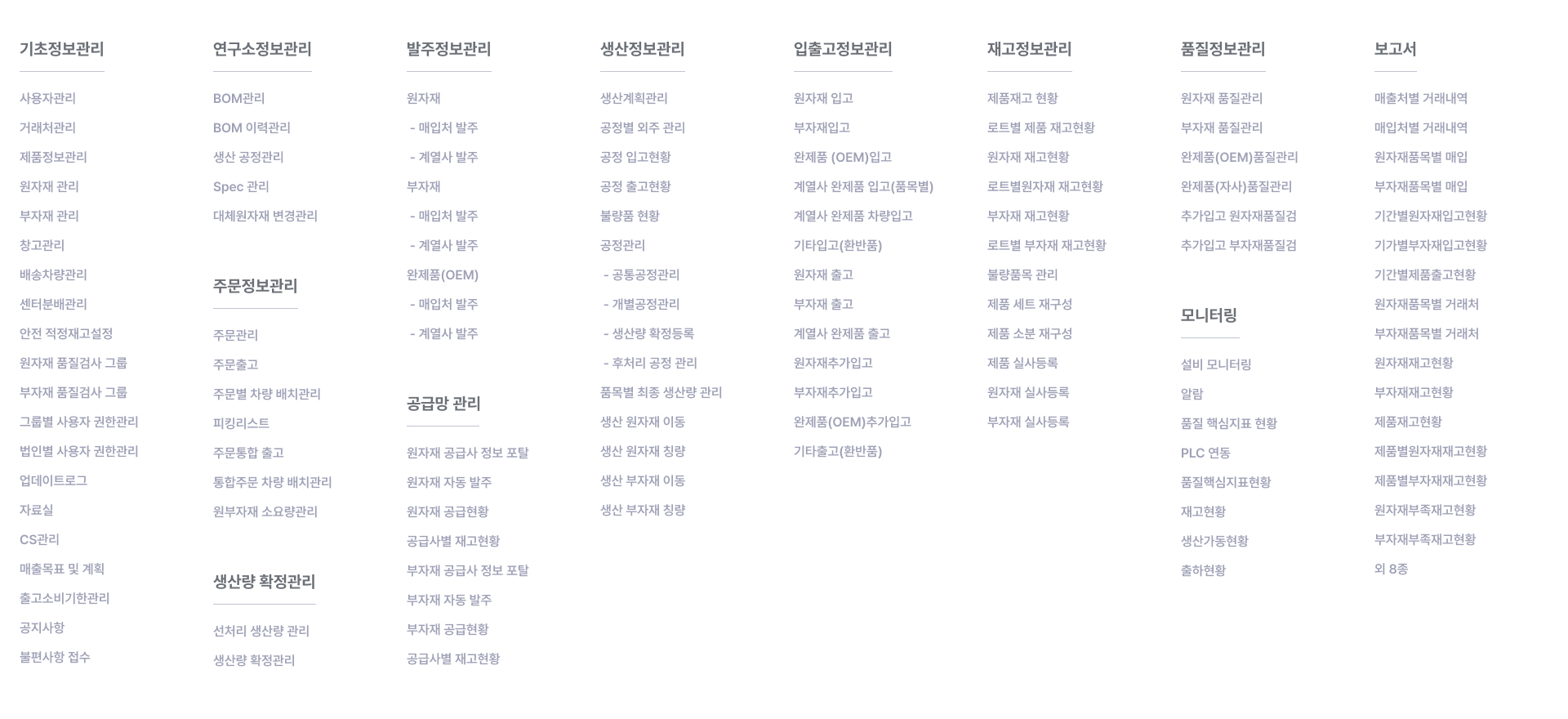

Manufacturing TraceabilitySyncWorks Menu Structure

"SyncWorks" is based on a standardized basic information management framework and consists of 12 menu groups. With its flexible modular design,

it can be optimized for any manufacturing industry, providing an intuitive and convenient interface tailored to each company.

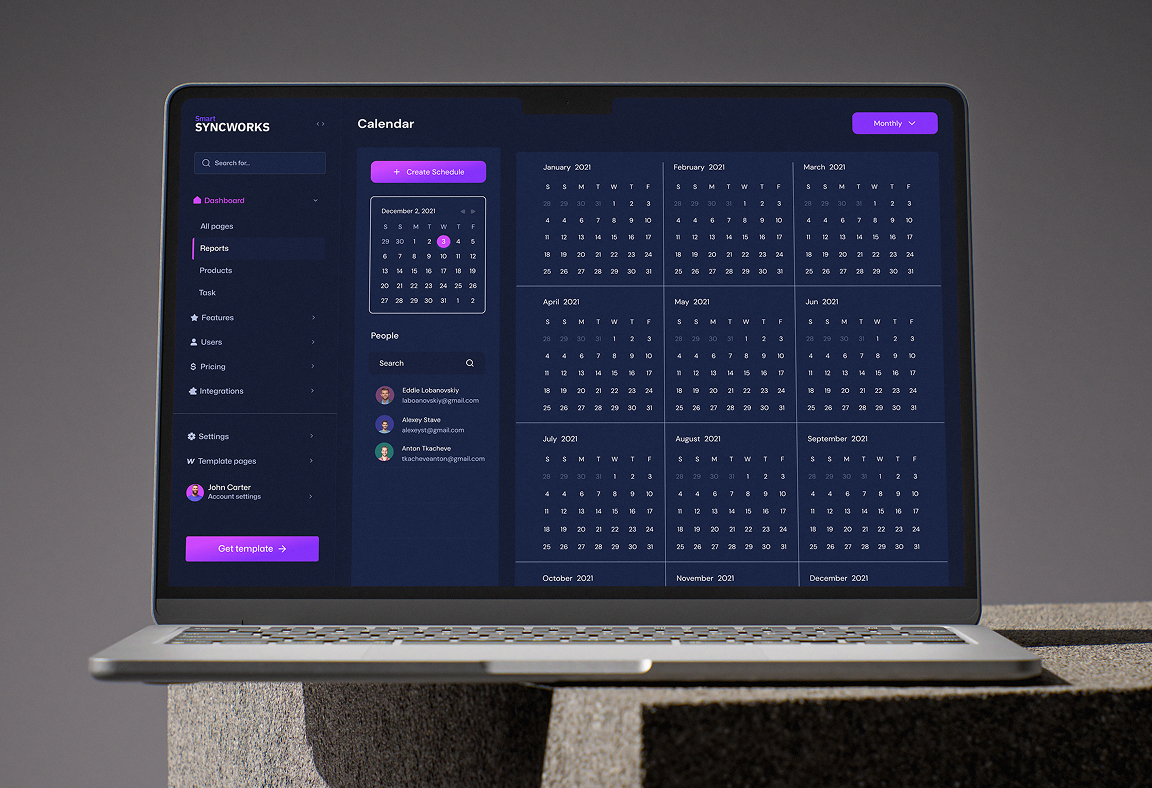

SyncWorks Interface Preview

SyncWorks Applied Technologies

"SyncWorks" is built on a robust, scalable, and easily integrable technology foundation.

Its system architecture emphasizes cloud-native design and modularity.