From Local Factories to Global Supply Chains,

SYNCWORKS Connects the Future of Manufacturing

Maximize productivity and minimize complexity.

SYNCWORKS addresses every challenge of modern manufacturing on a single platform.

Beyond Features, an MES That Works With You

Syncworks is more than a list of features—we prioritize user convenience and business growth

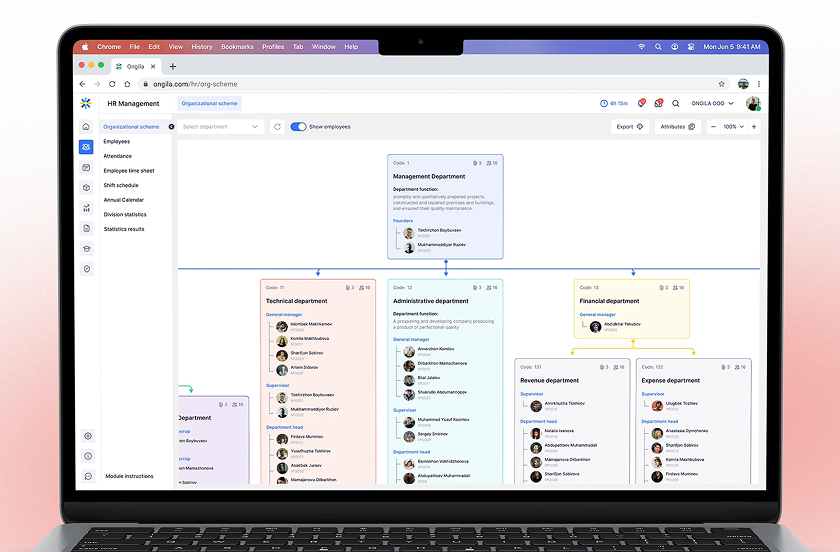

Instantly Empower

Everyone Like an Expert

Complex software creates friction, adds costs, and slows teams down.

Syncworks guarantees fast adoption with an intuitive interface and one-day onboarding.

One-Day Onboarding : Dramatically reduces training time for new employees.

Error Reduction : Intuitive design minimizes data entry mistakes.

A Platform That Evolves

With Your Business

Your ERP should move at the pace of your business. Syncworks adapts to your unique processes and expands with your growth through a flexible architecture.

Custom Workflows : Instead of forcing your work into the software, the software adapts to your work.

Future-Proof Investment : Flexibly scalable as your business grows, reducing total cost of ownership (TCO).

Instantly Empower

Everyone Like an Expert

ERP automates repetitive tasks, systematically consolidates performance data, and generates reports instantly—supporting efficiency and decision-making across the business.

Report Push : Automatically distribute monthly production, defect, and shipping reports.

Repetitive Task Automation : Reduce recurring tasks by 90% with automation.

These Challenges, Solved by SYNCWORKS

For the toughest challenges your business faces, Sync already has the solutions.

The Complete Toolkit for Manufacturing

Syncworks provides all the core capabilities your business needs to grow.

MES/POP

Track workflows in real time from order to completion. Automatically consolidate production data by equipment and process.

Inventory Management

From material receipts to warehouse stock, updates are automatic. Alerts prevent shortages and overstock.

QMS

Automatically collect defect history and generate statistics. Monitor process-level quality trends with detailed reports.

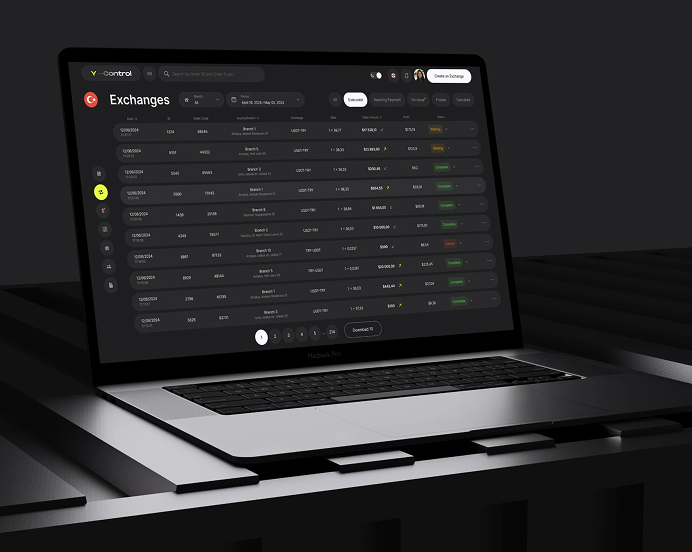

Sales&Order

Seamlessly integrate order, production, and delivery to meet deadlines. Track shipping progress in real time.

Take Your Business to the Next Level

Syncworks experts will analyze your current processes for free and identify key areas

for improvement in productivity, cost, and quality.